|

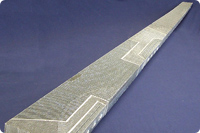

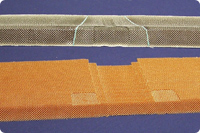

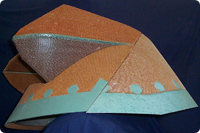

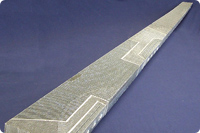

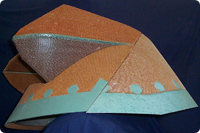

Texas Almet's familiarity with honeycomb and foam cores, adhesive core splicing / stabilizing / septumizing, as well as final assembly foam / film adhesive bond requirements, allows our customer to minimize fit-check and pre-fit times. |

| Purchasing complete "drop-in" honeycomb parts from Texas Almet allows our customers to focus on their core competencies of final bonding and assembly. |

|

|

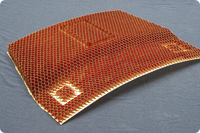

Value-Added processing begins with honeycomb or foam core material. Using conventional CAD/CAM techniques combined with our staff's extensive composites manufacturing expertise, Texas Almet then forms, bonds and machines a completed detail. |

Texas Almet's process capabilities include:

- Slicing & sawing

- Precision handwork rout, trim and chamfer operations

- NC programming, in-house tool design and fabrication

- HOBE® machining

- 5-axis NC tool and part machining

- Oven processing

|

|